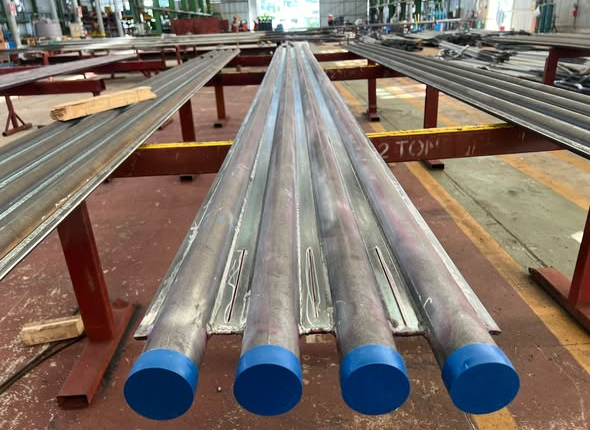

Material: ASTM A213 TP347H

These austenitic stainless steel tubes are precisely bent and subjected to post-bending heat treatment to relieve residual stresses and restore material properties. The discoloration seen is typical of heat-treated surfaces, indicating controlled thermal exposure to meet high-temperature service requirements.

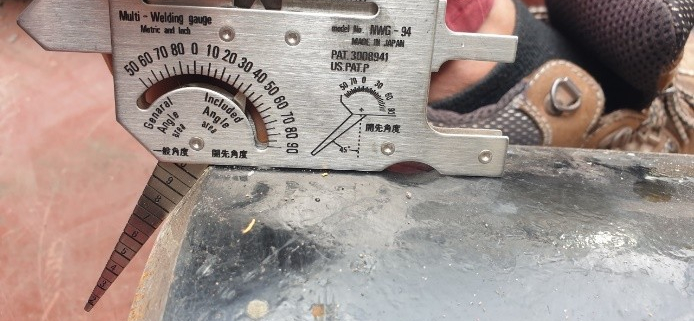

Fin-welded membrane panels fabricated to tight tolerances to ensure pressure part integrity and optimized heat absorption in the furnace zone. All welding joints are prepared for further NDT prior to final painting and dispatch.

At AGON PACIFIC, we ensure all fabrication processes strictly follow ASME Section I and customer specifications, including WPS/PQR, material traceability, and dimensional QC.