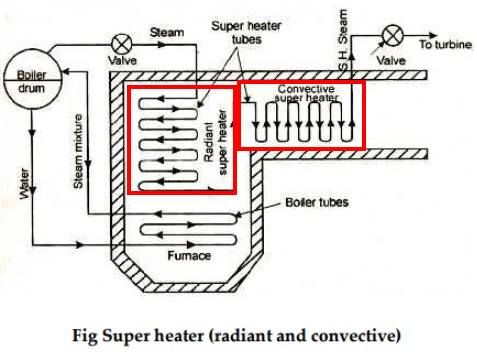

The Superheater is one of the most critical boiler pressure parts. Its main job: turn saturated steam into superheated steam – stronger, drier, and more efficient.

Key Functions

Radiant Superheater – absorbs heat directly from furnace radiation

Convection Superheater – heated by flue gas flow after furnace

Combined Superheater – uses both radiation + convection for optimum performance

At AGON Pacific, we ensure mechanical design and fabrication under ASME Code:

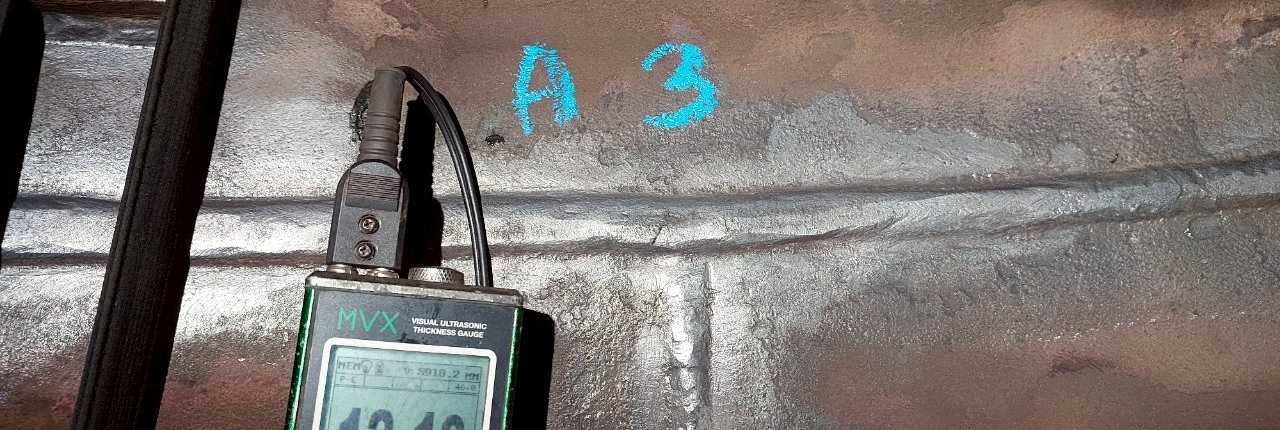

ASME Section I – thickness, stress, and allowable design

Materials – SA213 T22, T91, TP347H, creep-resistant alloys

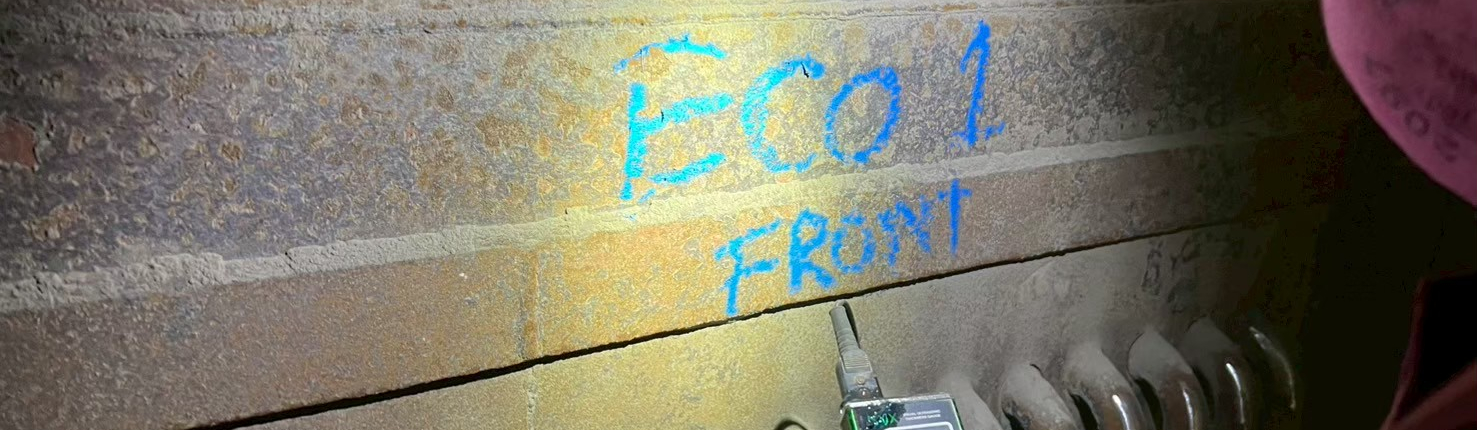

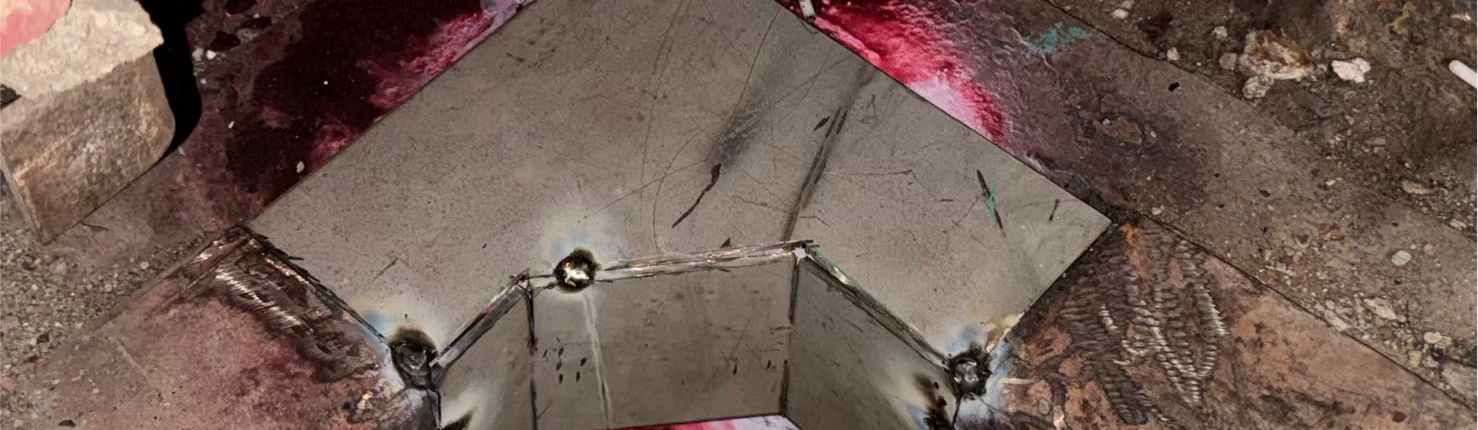

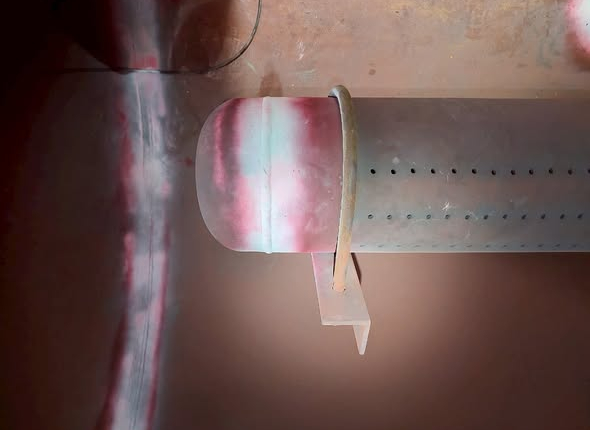

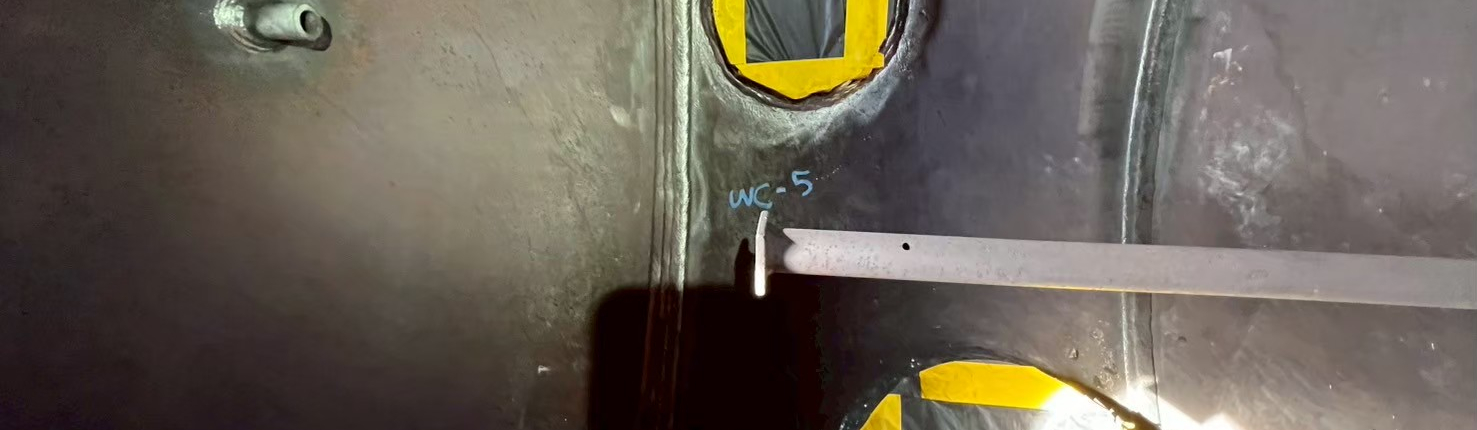

Fabrication – precision coil bending, header welding, nozzle prep

Quality Control – RT/UT, hydrostatic test, dimensional checks