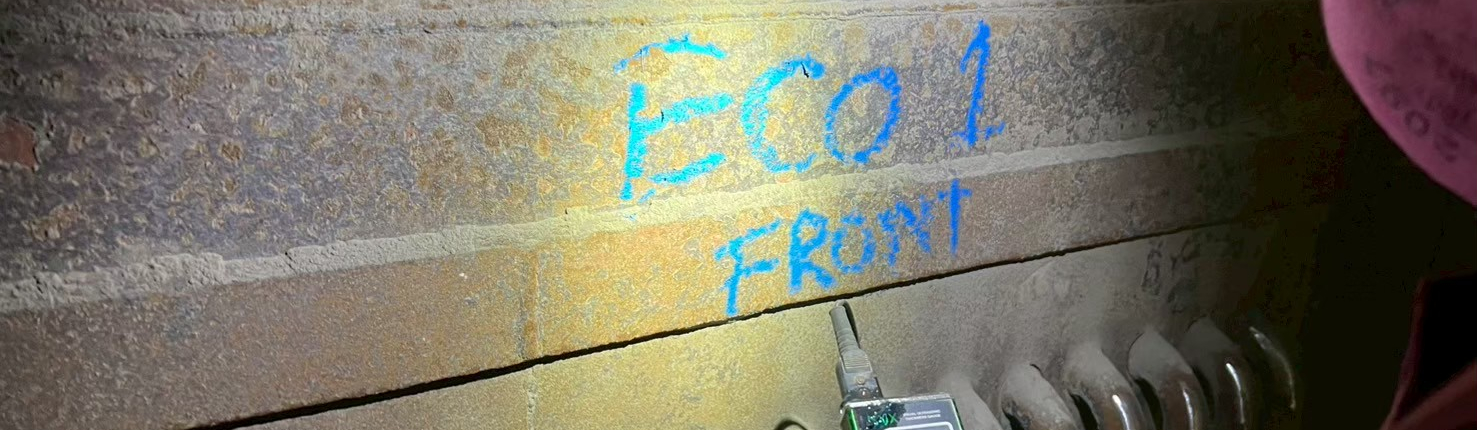

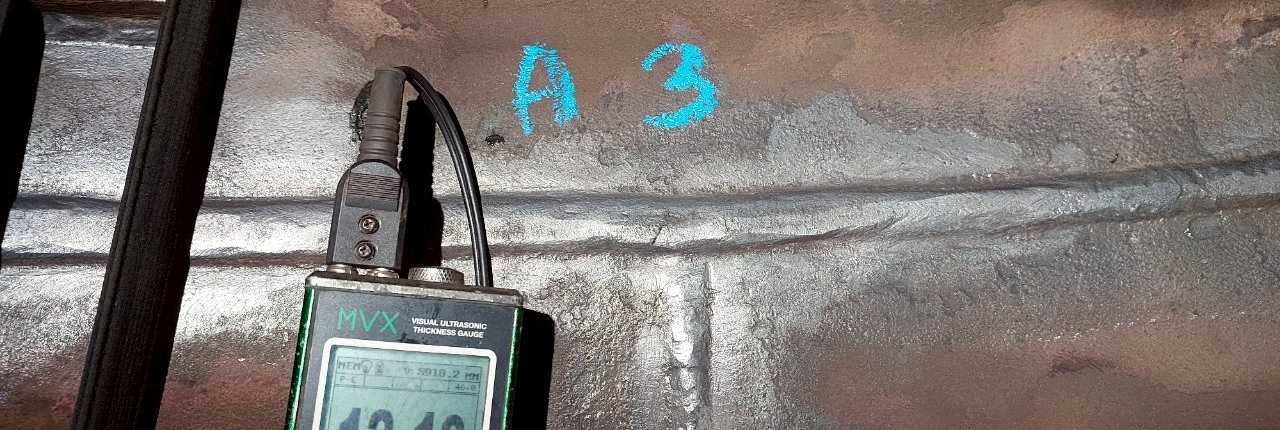

Agon Pacific successfully carried out a complete cleaning and inspection program for furnace and boiler systems — including hand-cleaning of grate zones, clinker removal, UT thickness testing, NDT inspection, and TEKE Cleaning of boiler heat transfer surfaces (Superheater, Economizer, Evaporator, Wall Tube).

Boost boiler performance and reliability.

Trust Agon Pacific for expert inspection, TEKE cleaning, and shutdown maintenance.

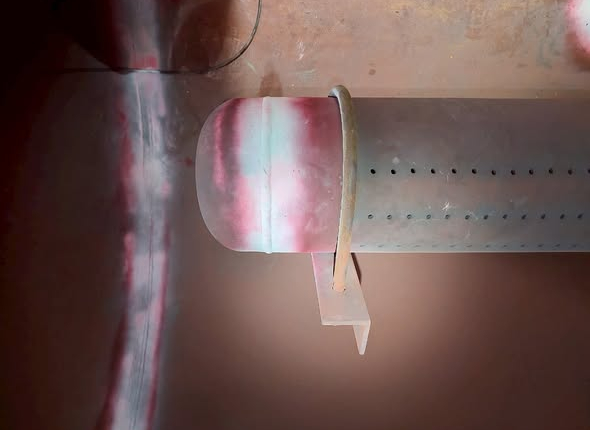

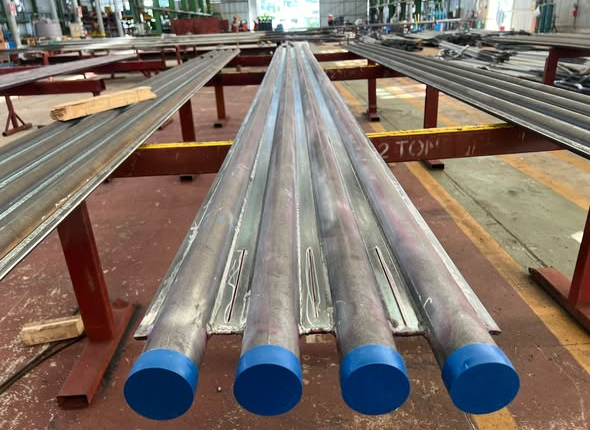

Material: ASTM A213 TP347H

These austenitic stainless steel tubes are precisely bent and subjected to post-bending heat treatment to relieve residual stresses and restore material properties. The discoloration seen is typical of heat-treated surfaces, indicating controlled thermal exposure to meet high-temperature service requirements.

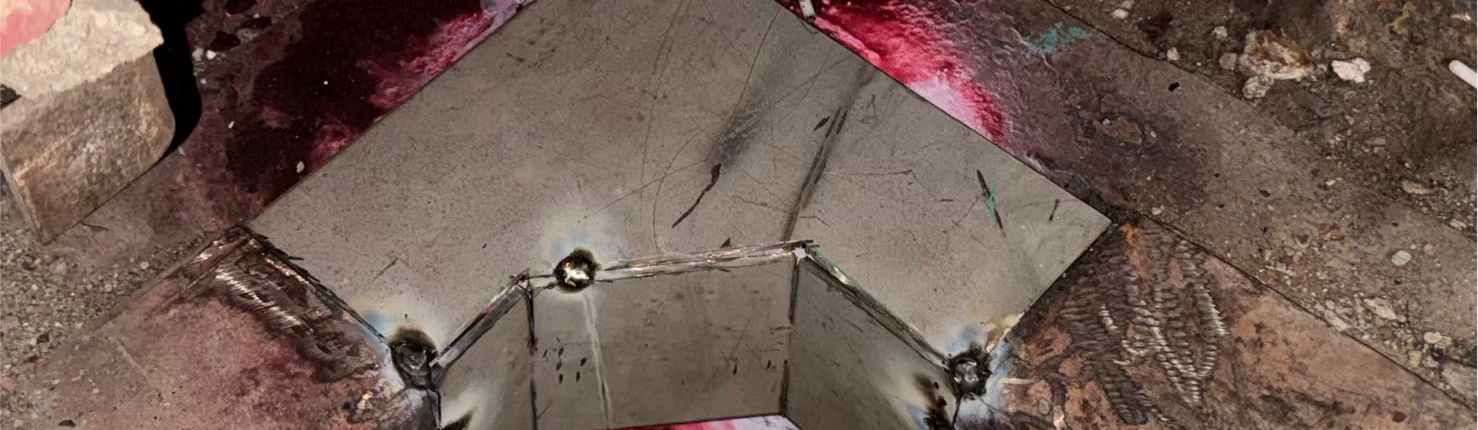

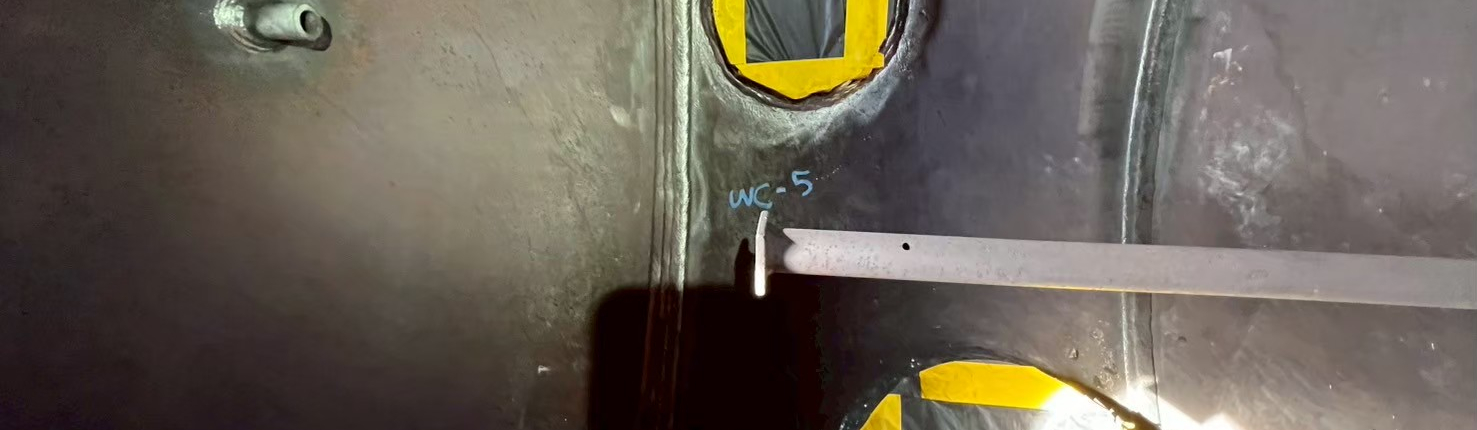

Fin-welded membrane panels fabricated to tight tolerances to ensure pressure part integrity and optimized heat absorption in the furnace zone. All welding joints are prepared for further NDT prior to final painting and dispatch.

At AGON PACIFIC, we ensure all fabrication processes strictly follow ASME Section I and customer specifications, including WPS/PQR, material traceability, and dimensional QC.

We are proud to announce the successful completion of the boiler wall panel replacement at the Airport Intake Panel.

Blog Posts

The 20 latest Blog Posts

- Zero failures. One full year of smooth operation.

- The news from AGON PACIFIC!

- See you again for Unit 1 inspection – New Year 2026!

- Project Wrap – Boiler Superheater Replacement

- Our customers keep coming back — and that’s why we give our best every day!

- Why TEKE Cleaning is the Smarter Choice?

- Superheater – Engineered for Performance & Reliability

- Hot Bend vs Cold Bend – Key Differences

- Water Wall Panel – Ready for Shipment

- Furnace & Boiler Cleaning and Inspection

- Boiler Pressure Parts Fabrication – AGON PACIFIC

- Project Completion Update – Boiler Wall Panel Replacement

- Packing Quality You Can Rely On!

- Economizer Fabrication Work

- We’re proud to be on-site at the SCG Cement plant

- Exciting News from Agon Pacific!

- Enhancing Heat Performance for Sustainable Energy Solutions

- Smooth Transition, Powered by Collaboration!

- We proudly announce that Agon Pacific has been awarded Rank A in the Supplier Performance Evaluation by Siam City Cement (SCCC)!

- Delivery Update | Economizer Module and Superheater Module

Pages

Available Pages

- About Us

- Agon Pacific In Brief

- Boiler Inspection

- Boiler Maintenance

- Boiler Pressure Parts Manufacturing

- Boiler Upgrade and Modification

- capabilities

- Certification

- Contact Us

- CSR Activities

- Home

- Job Dashboard

- Jobs

- Mission and Vision

- News

- Our Business

- Our Services

- Projects

- Quality Policy

- Spare Parts and Material Supply

- Submit Job Form

- Technical Consulting and Engineering Service

Categories

Archives by Subject:

Monthly

Archives by Month:

- October 2025

- September 2025

- August 2025

- July 2025

- May 2025

- April 2025

- March 2025

- February 2025

- December 2024

- September 2024

- August 2024

- July 2024

- May 2024

- April 2024

- March 2024

- December 2023

- October 2023

- August 2023

- July 2023

- May 2023

- March 2023

- December 2022

- April 2021

- November 2020

- April 2020

- February 2020

- January 2020

- December 2019

- May 2019

- February 2019

- January 2019

- December 2018

- October 2018

- September 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- June 2017

- January 2017